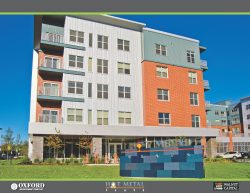

Oxford’s Hot Metal Flats Receives LEED Gold Certification

Hot Metal Flats. Image courtesy of Oxford Development

Oxford Development Company and its partners announced that the 117-unit Hot Metal Flats apartment complex in the South Side Works development in Pittsburgh has received LEED® Gold certification. The LEED rating system, developed by the U.S. Green Building Council (USGBC), is the foremost program for buildings, homes, and communities that are designed, constructed, maintained, and operated for improved environmental and human health performance.

“Our philosophy with multifamily projects is to create sustainable communities with their own individual identities,” said Steve Guy, President and CEO, Oxford Development Company. “With a great project team we were able to exceed our certification expectations for this project and provide residents with a safe, healthy dwelling in a fun and active neighborhood.”

Hot Metal Flats achieved LEED certification for implementing practical and measurable strategies and solutions aimed at achieving high performance in: sustainable site development, water savings, energy efficiency, materials selection and indoor environmental quality.

“We spend 90 percent of our time indoors, so where we live greatly impacts our health and well-being,” said Rick Fedrizzi, CEO & founding chair, USGBC. “By achieving LEED Gold certification, Hot Metal Flats has become a place that anyone will truly love to call home, not only because it’s energy and water efficient, but because its designed with the health of its inhabitants in mind.”

evolveEA served as Sustainability Consultant to the project team, which also includes:

P.J. Dick – Construction Manager,

Walnut Capital – Property Manager,

WTW Architects – Architect of Record,

Loftus Engineers – Mechanical Engineer,

Civil Environmental Consultants – Civil Engineer,

Advantus Engineers – Commissioning Agent,

and LaQuatra Bonci – Landscape Architect

“We led early goal setting meetings with the team in order to determine and prioritize sustainability goals, for which the final project has delivered,” stated Marc Mondor, AIA, LEED Fellow, Principal of evolveEA. “Gold level certifications don’t happen by chance.”

Through the design and construction efforts of the team, the project expects a significant reduction in energy consumption by approximately 20 percent and water use by 40 percent as compared to a similar baseline project. The building construction practices led the project to divert more than 86 percent of the waste generated by the on-site construction activities to destinations other than landfills. Nearly 38 percent of the building materials purchased for the project were manufactured and extracted from regional sources and nearly 22 percent of the total building materials were manufactured using recycled materials.

“Hot Metal Flats is yet another example of why Pittsburgh is the most livable city,” said Clifford Rowe, CEO, PJ Dick. “Residents can be proud that they are living in a building that was built with a commitment to sustainability, from the reuse of brownfields to the incorporation of green design and construction.”

As a brownfield development project in an urban location, Hot Metal Flats reuses a piece of land in close proximity to the riverfront which had been damaged by the steel mill formerly located on the site. Through the efforts of the Urban Redevelopment Authority (URA), the site was purchased, cleared and entered into the PADEP Act 2 program in preparation for redevelopment. The Oxford team, with assistance from the URA, completed the site preparation activities by removing existing foundations and historic fill, much of which was processed and reused onsite to provide a suitable building pad, and was responsible for remediation in accordance with the site Act 2 guidelines.

Access to public and alternative transportation methods and connection to community scored high with the project’s location in the dynamic South Side Works community. The inclusion of EV charging stations and bicycle storage also contributed to this aspect.

But the most beneficial measures for residents have been taken in the design, construction and maintenance of the interior spaces. The building provides an improved indoor environment for tenants through the incorporation of low emitting paints, sealants and flooring materials. These materials incorporate a minimum amount of Volatile Organic Compounds (VOC) which have proven to have long term health impacts, especially in residential settings. Maintenance is undertaken utilizing green and sustainable products. The spaces were also designed to provide a significant amount of natural daylighting in living spaces – Hot Metal Flats has provided direct line of sight views from nearly 99 percent of all regularly occupied spaces.

More information about Hot Metal Flats is available at hotmetalapartments.com.